Smits Cheese

Valuable cheese for human consumption!

Food

Smits Residual Flows

Circular food processing

Food

Smits Biva

Animal feed with a fixed basis: former foodstuffs

Feed

Construction, engineering and logistics

Incompany innovation for technical installations, machines and housing

Other

Smits Zevenhuizen B.V.

Future proof

Smits Zevenhuizen is an innovative family company involved in the processing of residual waste and side-flows supplied by the food industry. By reusing these products, we produce high-quality animal feed and give residual cheese a new destination. This is how we contribute to the reduction of food waste and the development of a more circular food industry!

Your residual waste, our resource!

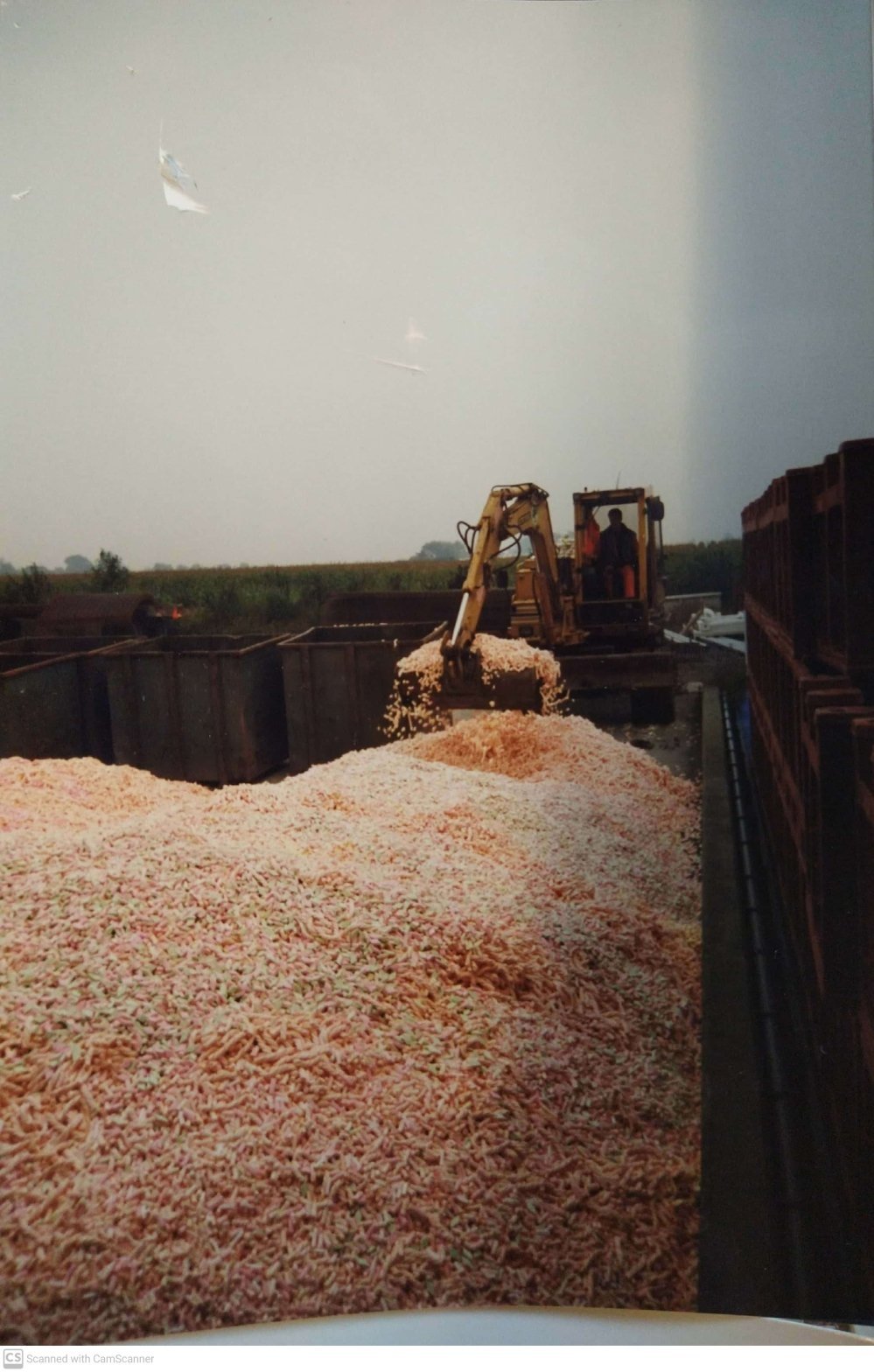

The residual products, such as confectionery, biscuits, chocolate, cheese, etc. that we collect from manufacturers throughout Europe become the raw materials for a new product. Our sustainable finished products are used in the food industry and agricultural sector.

Creating 'value' with innovation

A crucial motive of Smits is to "value the highest possible value" of residual flows. That is why we create our own technical solutions with an internal technical department.

Food & Feed

Our production is divided into two flows: Feed & Food. Our Food department mainly collects cheese products with an unsuitable shape or weight and processes them to become semi-finished products that are then used to make new products for human consumption. The Feed department collects residual flows that are processed to become high-quality animal feed.

Unburden and reduction

We find effective ways to reuse food products through innovative processes and with a strong focus on quality. With our services, we relieve clients and suppliers of their residual waste flows, which also gives them better insight into the residual waste volumes they produce. This is a great way to reduce waste together.

Long term

We focus on long-term relationships and sustainable collaborations. We continuously look for ways to respond to the needs of our clients and suppliers so our services never cease to add value effectively.

Jobs

The Smits organisation consists of several departments: Logistics, Technical Services, Cheese, Feed, and Support.

We aim for long-term relationships so we can build on a sustainable future together. That is why we invest in the development of our employees, in maintaining excellent relationships with our clients and suppliers, all based on ‘trust, expertise, and ownership’.

We also have a variety of opportunities for traineeships and (academic) final thesis projects.

At Smits, click here for our vacancies.

Onze geschiedenis

De geschiedenis van Smits Zevenhuizen. (EN)

2022

New construction in full swing!

2021

Start new construction for better automation and inventory management

2014

Construction has started on the 'De Boog' building, named after the roof shape. The building houses the workshop/machine factory of the TD, the office for the Expedition and the storage hall for the empty bins.

2008

A fire in the production halls halted production in 2008. After hard work from the entire team, we got this back on track within a month.

1996

Because the permit for pig stables in Zevenhuizen did not work out immediately, Smits started a pig farm in Vorden. After 6 years, the construction of the stables in Zevenhuizen with a capacity of 5,000 pigs started.

1989

Smits puts a lot of energy into the development of new machines. This year Smits built the 1st version of the cistern for feed production. The beginning of the common and unique processing method.

1989

In 1989, the Smits Brothers left Hazerswoude-Rijndijk for the construction of the N11. Feed production and cheese processing are being further optimized on a new piece of land in Zevenhuizen.

1984

Because good pieces of cheese also came in through dairies, a new process was started in 1984 for the reuse of the cheese for human consumption.

1983

Due to high feed prices, the Brothers Smits started looking for alternatives. Contact was made with food manufacturers. This was the start of circular feed production for pigs.